What is the difference between stainless steel and aluminum accessories?

- Durability

- Corrosion resistance

- Machinability and versatility

- Thermal and electrical conductivity

- Cost

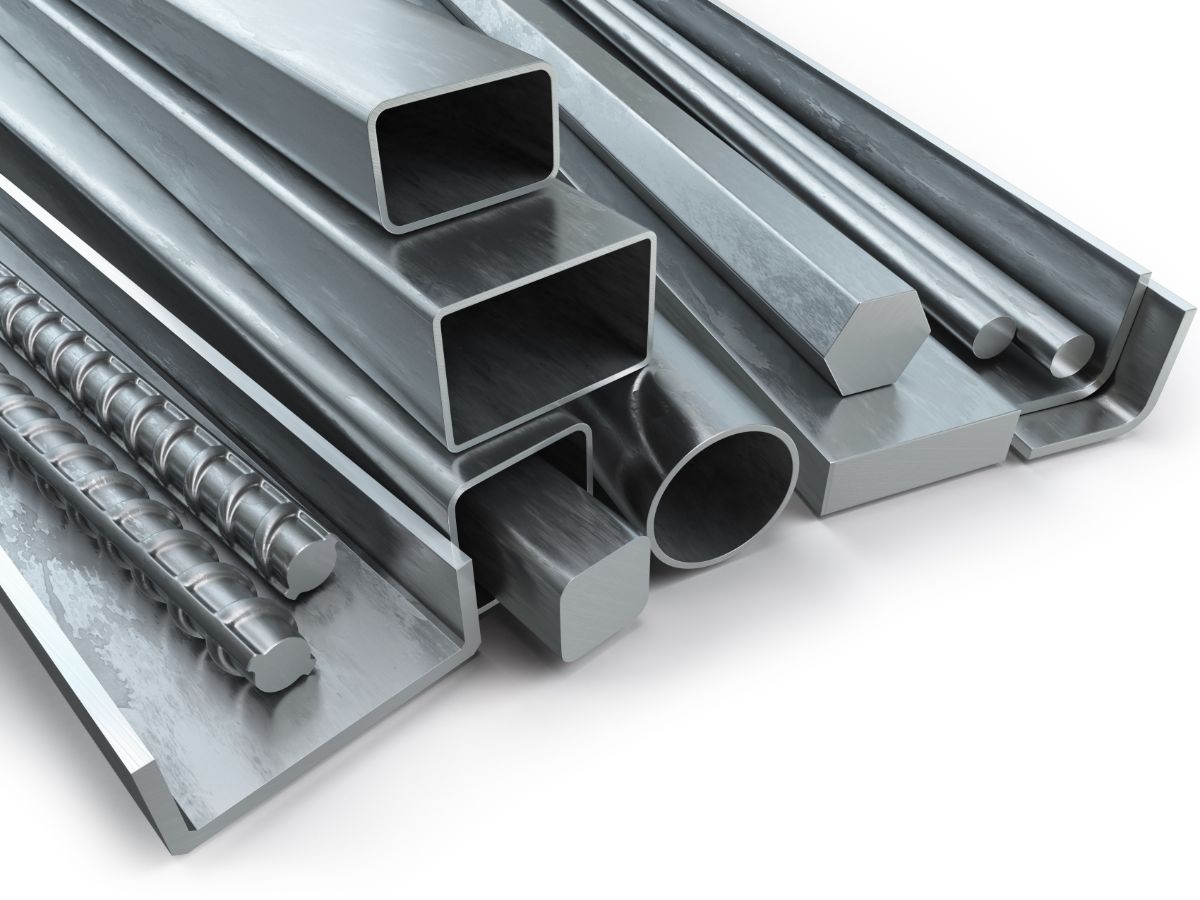

There are two types of materials that are widely used in today’s construction projects: aluminum and steel accessories. These are utilized for various applications in different industries such as the automotive, aerospace, consumer goods, electronics, and construction industry. For several decades, many have been wondering what is the difference between stainless steel and aluminum accessories, and which is the best material.

Both stainless steel and aluminum accessories have strong points. Stainless steel is known for being durable, while aluminum is known to have the best strength-to-weight ratio. Before you choose which material to use for your project, knowing these key differences between stainless steel and aluminum accessories in terms of durability, corrosion resistance, machinability and versatility, thermal and electrical conductivity, and cost can help provide you with the best investment value.

Durability

Stainless steel accessories are known to be stronger than aluminum accessories because of their high chromium content. The chromium content improves hardness and tensile strength to 505 MPa. Aluminum has a tensile strength of about 276 MPa.

Tensile strength refers to the maximum load a material can support when being stretched without getting fractured. However, aluminum is lighter than steel and has a higher strength-to-weight ratio.

Aluminum accessories are around 33% lighter than stainless steel accessories, making them more ideal for industrial applications that need strength and reduce the weight of different products.

In addition, aluminum accessories become harder when the temperature is extremely low. On the other hand, stainless steel becomes brittle under low temperatures, which can affect its durability.

Corrosion Resistance

Corrosion resistance is also an important consideration when evaluating the durability of a material. Corrosion is a natural process that occurs when the surface of a metal oxidizes, which causes damage. Both stainless steel and aluminum accessories are corrosion resistant.

Stainless steel accessories are corrosion resistant because they have a protective chromium film and are also non-porous. However, stainless steel is an alloy made of iron, chromium, nickels, and other metals. Aluminum accessories exhibit better corrosion resistance without any further treatment because they do not contain iron. When exposed to the atmosphere, aluminum oxidizes and produces a layer of aluminum oxide. What’s interesting is that aluminum oxide protects the aluminum accessories’ interiors from further corroding. In addition, aluminum can be further protected from corrosion with powder coating or anodizing. This is why aluminum accessories are ideal for outdoor applications that are constantly exposed to weathering.

If you need window locks, handles, or hinges, for example, you would be better off choosing aluminum as the material as it gives an extra level of corrosion resistance.

Machinability and Versatility

Aluminum is more machinable and versatile than stainless steel. To be exact, aluminum can be machined up to three to four times faster than stainless steel. This is because aluminum is lightweight, soft, and very ductile. It can be successfully cut, bent, folded, shaped, and formed into different accessory shapes or profiles without cracking or fracturing. Stainless steel is harder to form, making it more difficult to work with when you need accessories.

If you need your accessories to be cut in specific sizes or shapes, it would be much more efficient to choose aluminum. With aluminum, it would also be much easier to accommodate material alterations in the future.

Thermal and Electrical Conductivity

One would think that stainless steel is a thermal and electrical conductor because it is a metal alloy. However, stainless steel has less thermal and electrical conductivity than aluminum. In fact, stainless steel has less thermal and electrical conductivity than copper, zinc, brass, bronze, nickel, and other metals.

Compare this to aluminum, which has excellent electrical conductivity. This is why aluminum accessories are widely used for air conditioning units, high-voltage power lines, electrical conduits, and computer motherboards.

Cost

Cost is one of the top considerations when choosing a material to use for projects. For a good reason, project owners want to ensure they get the best value for their money. In terms of raw material, stainless steel is cheaper than aluminum. However, the prices of these two materials when created as accessories should always be taken into consideration.

Aluminum is the most abundant metal on the planet, making up more than 8% of the Earth’s core mass. Aluminum is also the third most common chemical next to oxygen and silicon. Aluminum is also lightweight, making it easy to fabricate and transport. This reduces the price of aluminum accessories on the market. On the other hand, stainless steel accessories can be more costly because of the presence of other alloying metals like chromium and iron.

Key Takeaway

In choosing between aluminum accessories and stainless steel accessories, it’s crucial to understand the difference of each material. In this guide, we’ve outlined the difference between stainless steel and aluminum accessories based on factors like durability, corrosion resistance, machinability and versatility, thermal and electrical conductivity, and cost.

While it is true that stainless steel accessories are stronger, several factors can make aluminum accessories more beneficial for your project.

In need of aluminum accessories in the Philippines? Check out Aluminum Depot’s wide array of aluminum accessory products that are durable and built to last. Request a quotation by contacting Aluminum Depot here.