What are the different applications of aluminum sheets?

- Vehicle parts

- Aircraft and aerospace vehicle parts

- Packaging

- Kitchen appliances and cookware

- Construction materials

Aluminum sheets are a widely preferred material because of their properties:

- Corrosion-resistant

- Lightweight

- Durable

- Affordable

- Electrically conductive

- Thermally conductive

- Ductile

- Eco-friendly

Also highly malleable, aluminum sheet materials. Let’s take a closer look at the different applications of aluminum sheets and how industries make use of them.

What Are Aluminum Sheets?

Simply put, aluminum sheets are the product formed when aluminum is pressed and rolled into thin panels under great pressure.

Aluminum sheets are lightweight yet durable enough for a variety of applications. These also come in different thicknesses and sizes. The versatility of aluminum sheets is further boosted by their easy installation and low maintenance.

In addition, different finishing options can be applied to aluminum sheets. For example, they can be powder coated for added design and improved corrosion resistance.

Vehicle Parts

Aluminum sheets have been used to manufacture vehicles for over a hundred years already. This is because aluminum has an excellent strength-to-weight ratio. Unlike steel, it is light yet durable.

Today, the automotive industry has paid more attention to reducing the weight of their vehicles because this is the key to meeting strict CO2 emission targets. Lighter vehicles also allow higher acceleration and minimized fuel consumption.

Did you know that every 1 kilo of aluminum used in a vehicle reduces the entire weight of the vehicle by 1 kilo? This is why more and more vehicle parts are being produced from aluminum. In the production of the following vehicle parts, composite panels from aluminum sheets are used:

- Vehicle framing (hood, body, bumper)

- Suspension parts

- Engine radiators

- Engine pistons

- Wheels

- Engine cylinder head

- Magnets for speedometers, airbags, and tachometers

- Transmission bodie

- Air conditioner pipes and condenser

- Plate numbers

Another reason why aluminum sheets are preferred for the production of vehicle parts is that when it gets bent, the deformation is localized to the impact area. The rest of the vehicle’s body maintains its original shape and helps in keeping passengers safe. In the next few years, we could foresee more vehicles made completely with aluminum sheets and components.

Aircraft and Aerospace Vehicle Parts

Aluminum sheets are also popular in aircraft construction and the manufacture of aerospace vehicle parts.

Aircraft parts are assembled from aluminum sheets and extrusions and are attached together by rivers. Planes need to be as light as possible, use the least amount of fuel, and have bodies that don’t rust over time. Flexible, light, corrosion-resistant, and durable, aluminum proves to be the most ideal material for building aircraft.

Here are some of the other aircraft parts made from aluminum sheets:

- Wing panes

- Exhaust pipes

- Refueling hoses

- Doors

- Floors

- Hydraulic systems

- Cabin pillars

- Ball bearings

- Cockpits

- Engine turbines

- Fuselage

- Trims

Aluminum sheets are indispensable not just in the aircraft industry, but also in aerospace where an excellent strength-to-weight ratio is crucial. Approximately 50% to 90% of modern aerospace vehicles are made from this sheet material.

Packaging

The ease of shaping aluminum sheets into virtually any shape makes it ideal for various packaging applications — from foil, drink cans, and essential canned goods, to bottle caps. Aluminum sheets are also corrosion resistant and have an anti-microbial layer. This makes them ideal for direct contact with food and beverages. Additionally, they are 100% recyclable, which helps the packaging industry in cutting down its carbon footprint.

Kitchen Appliances and Cookware

One of the top applications of aluminum sheets includes kitchen appliances and cookware. Given that aluminum sheets are lightweight, durable, and thermally conductive, they are the go-to material choice for creating a range of appliances, such as dryers, refrigerators, and washing machines.

Aluminum sheets are also used for saucepans, knives, spatulas, measuring spoons, measuring cups, can openers, graters, bowls, and more.

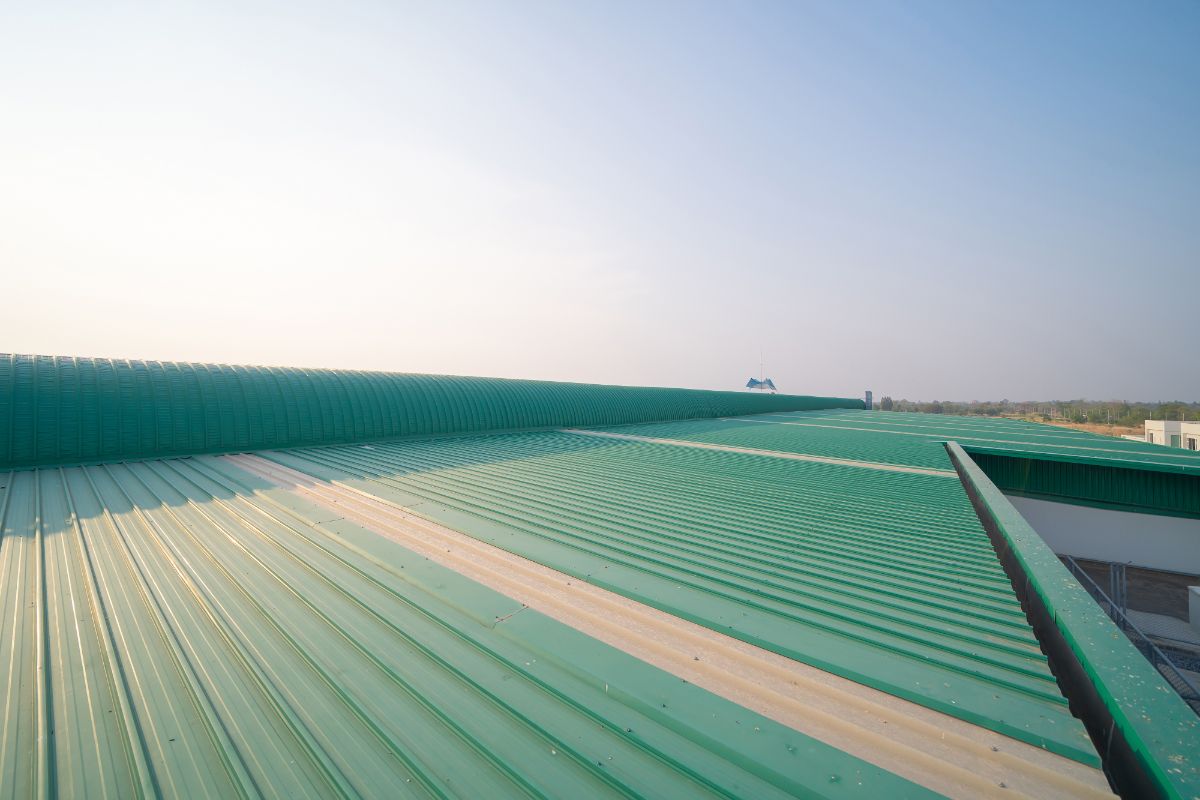

Construction Materials

Aluminum sheets have a wide array of applications within the construction industry. As said earlier, aluminum sheets are light, durable, corrosion-resistant, and can be formed into any desired shape. In the hands of engineers and architects, aluminum sheets can be creatively fashioned in many ways, which don’t compromise the building’s structural integrity.

Common construction materials that make use of aluminum sheets include drains, frameworks, gutters, siding, cladding, and roofing.

Key Takeaway

In this article, we’ve rounded up some common applications of aluminum sheets.

At Aluminum Depot, we are a reputable supplier of aluminum accessories in the Philippines. To find out more about our range of aluminum sheet accessories, click here. For other inquiries, simply contact us here.